At NOVO, we are committed to providing high-quality plastic products that meet and exceed industry standards through rigorous quality control measures at every step of the manufacturing process to ensure that our products are reliable, durable, and safe.

We adhere to internationally recognized quality standards, ensuring that each product we deliver meets strict criteria for performance, safety, and environmental impact. These standards are aligned with global best practices to support a wide range of industries, including automotive, medical, packaging, consumer goods, and more.

We are certified under ISO 9001:2015, the international standard for quality management systems. This certification reflects our commitment to continuously improving our processes, enhancing product quality, and ensuring customer satisfaction through systematic management and efficient operations.

We prioritize meeting customer-specific requirements, defect prevention, reducing variation, and waste. Our focus on the continual improvement process helps identify and address all areas of improvement throughout the management system. We strive to manufacture parts, components, and assemblies to the highest quality.

Our manufacturing processes are SQF certified and recognized by the Global Food Safety Initiative (GFSI). As a food and beverage packaging manufacturer, NOVO meets the industry, regulatory, and customer requirements for food safety and quality. Following the principles of HACCP, we always seek to identify and manage potential food hazards while implementing continuous improvement into the quality management system.

Quality begins with the selection of raw materials and is maintained through each step of the manufacturing process

We source premium raw materials from trusted suppliers, ensuring consistency in material properties. Materials are tested for key performance factors such as durability, flexibility, impact resistance, and heat resistance.

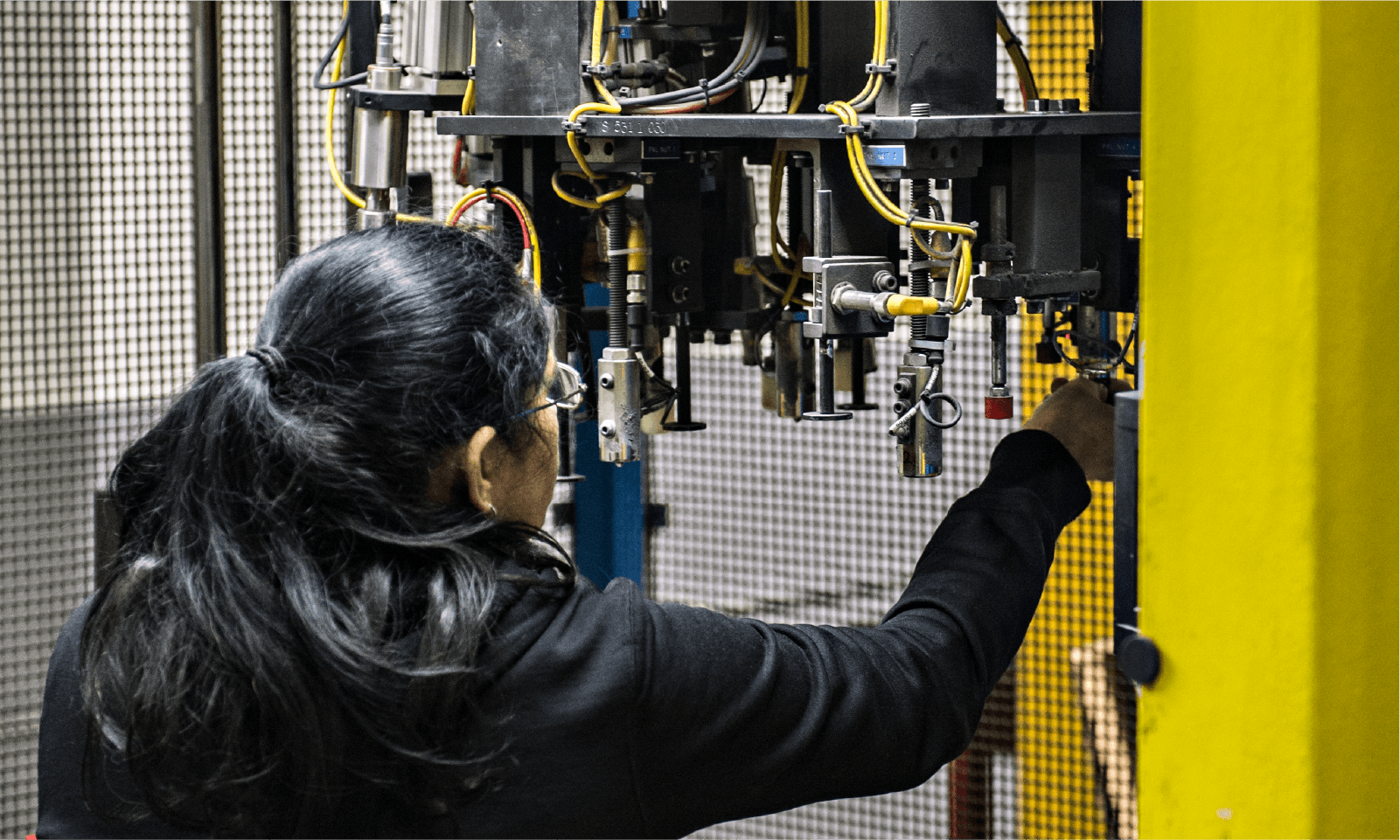

Using state-of-the-art machinery and cutting-edge techniques, we ensure precise molding and shaping of plastic components. Our in-house engineers and technicians monitor production at every stage to minimize defects.

Continuous testing is done during production to catch potential issues early. Automated inspection systems and manual quality checks ensure that each product meets our high standards.

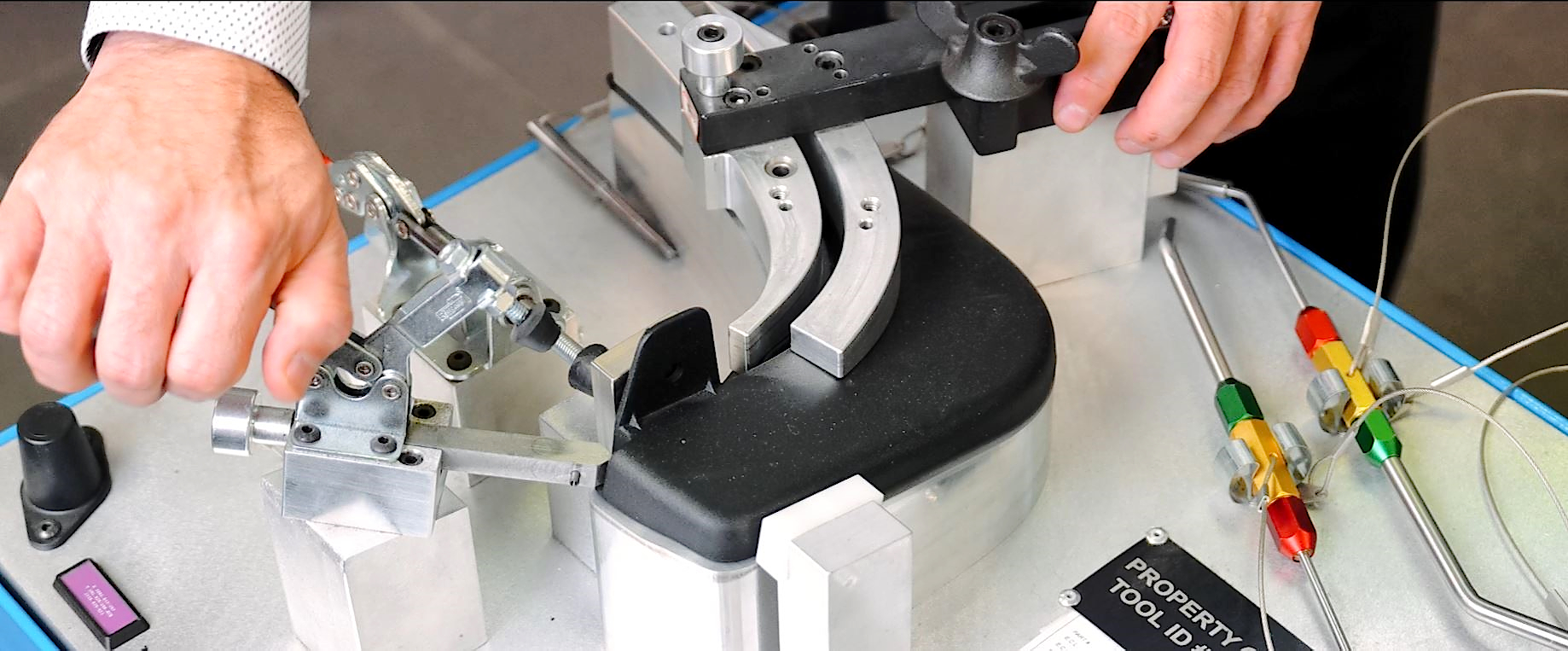

Every batch of products undergoes final inspection for dimensions, strength, surface quality, and performance. Products are subjected to rigorous tests such as tensile testing, chemical resistance tests, and load-bearing capacity to guarantee reliability.

Finished products are carefully packaged to avoid damage during transit. We conduct final checks on product packaging to ensure compliance with customer-specific requirements and international shipping standards.

We understand that each client has unique needs and specifications. Our team works closely with customers to ensure that their exact requirements are met, from custom product designs to packaging preferences. We value long-term partnerships, and our customer service team is always available to assist with any concerns or special requests.

At NOVO, quality is not a one-time goal; it’s an ongoing commitment. We continuously monitor industry advancements and invest in research and development to enhance our processes, ensuring that our products are always on the cutting edge of innovation.