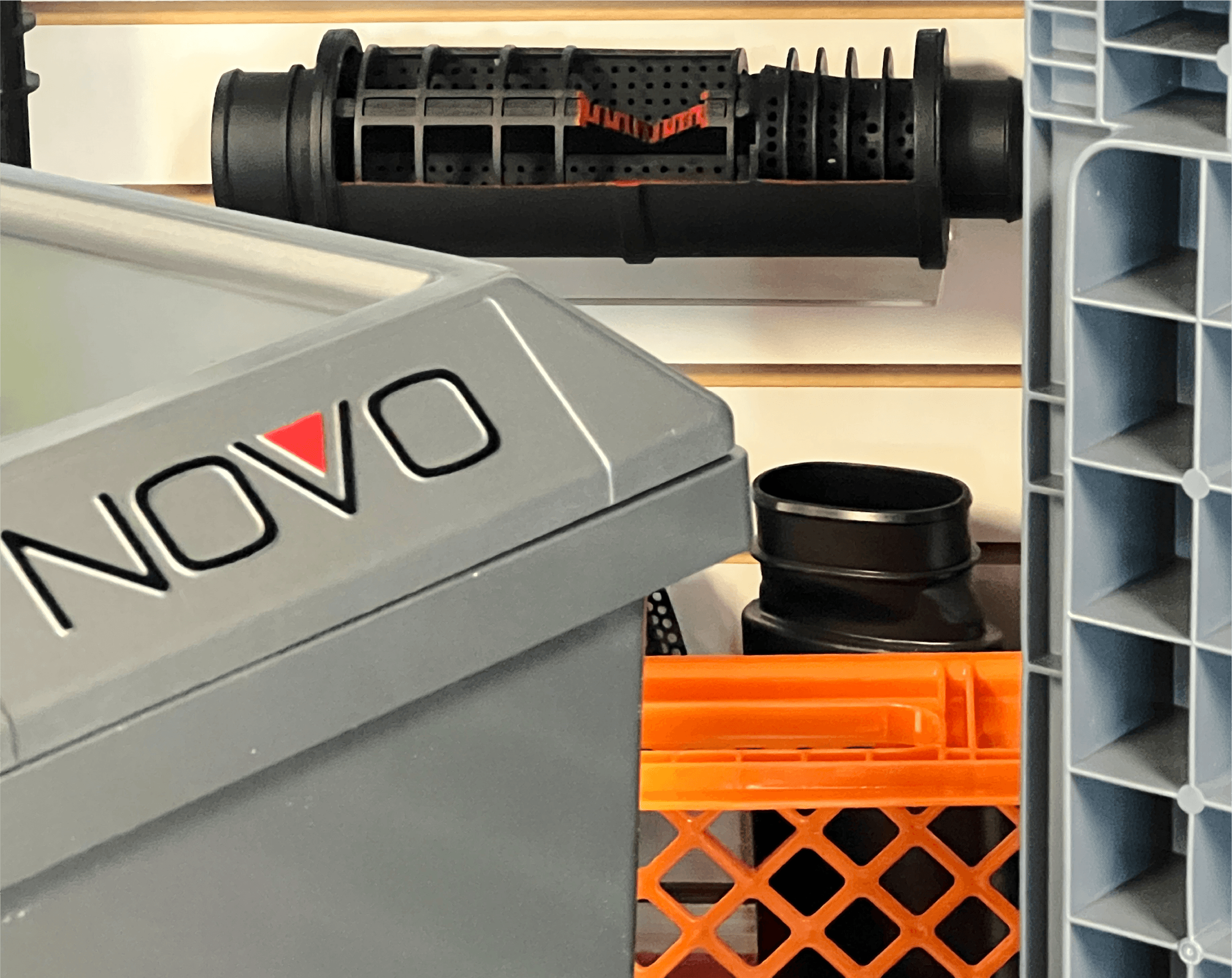

As a leading Canadian engineered plastic manufacturer, innovation is at the core of everything we do. Staying ahead of the curve requires continuous research and development to improve product quality, sustainability, enhance manufacturing processes, and meet the ever-evolving needs of our customers.

NOVO’s focus on R & D involves systematic efforts to develop new products, improve molding processes, enhance materials, and integrate advanced technologies like automation and sensors. The goal is to increase quality, reduce cycle times and costs, and stay competitive.

Our R&D team works closely with raw material suppliers and industry partners to develop high-performance, lightweight, and durable materials for a variety of applications. We focus on:

Researching and developing environmentally friendly materials to reduce the ecological impact of plastic waste.

Creating materials that withstand extreme temperatures, chemicals, and physical stress for use in automotive, aerospace, and industrial applications.

Innovating with post-consumer and post-industrial plastics to create products that are both sustainable and high-quality.

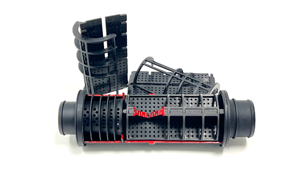

Our R&D team collaborates with customers to develop custom plastic solutions tailored to their specific needs. This includes:

Evolving an idea/concept into fruition with our team is seamless. Incorporating manufacturing knowledge at the design process will ensure a superior and sustainable product.

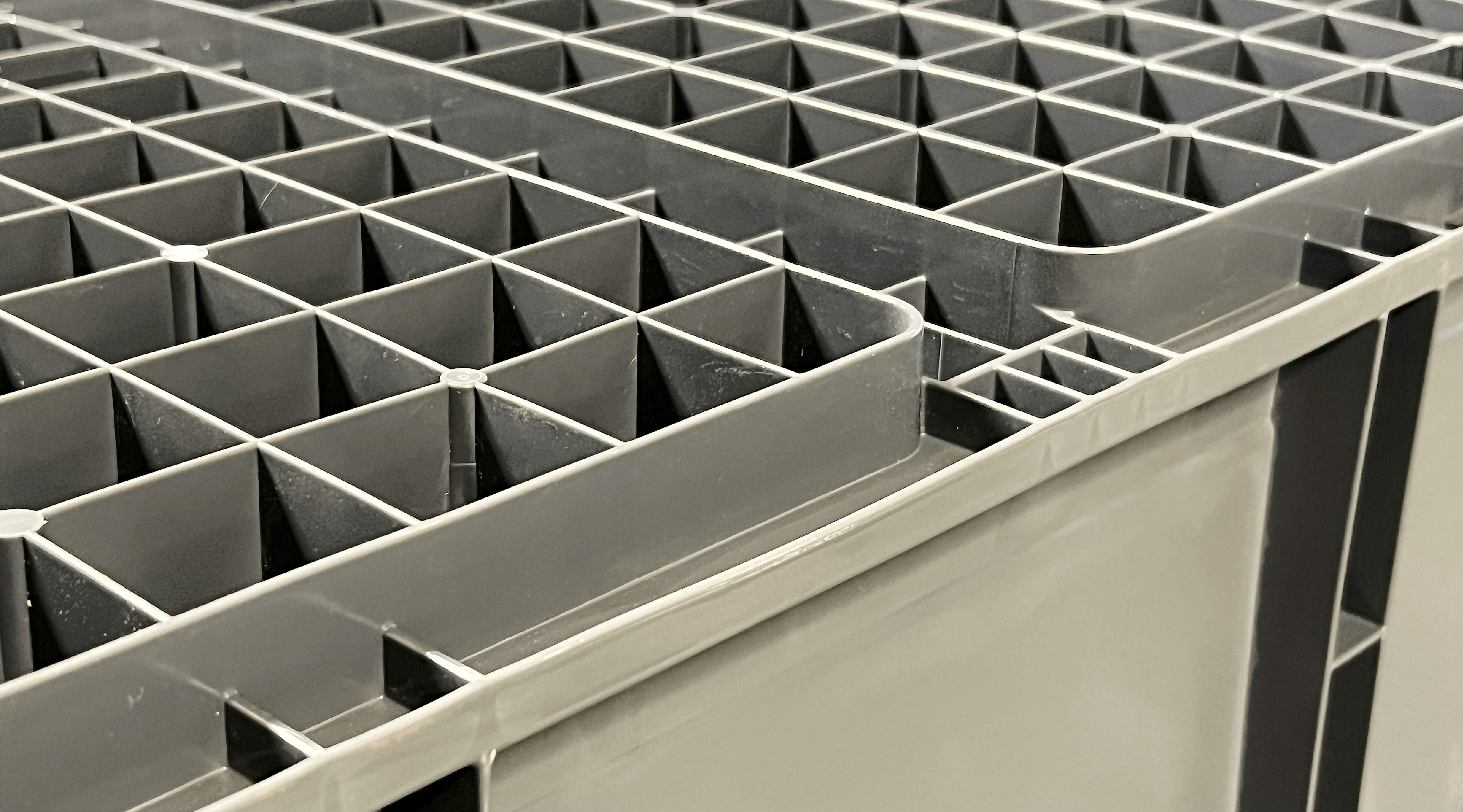

Using advanced 3D modeling and prototyping techniques to test and refine product designs before full-scale manufacturing.

We strive to improve efficiencies to produce complex, precise and sustainable parts.

Sustainability is at the heart of our R&D efforts. We continuously explore ways to reduce our environmental footprint through energy effeciency, waste reduction, and eco-friendly packaging.

Investing in machinery and technologies that minimize energy consumption during manufacturing.

Developing packaging solutions that use less material or are recyclable/compostable.

Innovating in recycling and upcycling to reduce plastic waste and contribute to the circular economy.

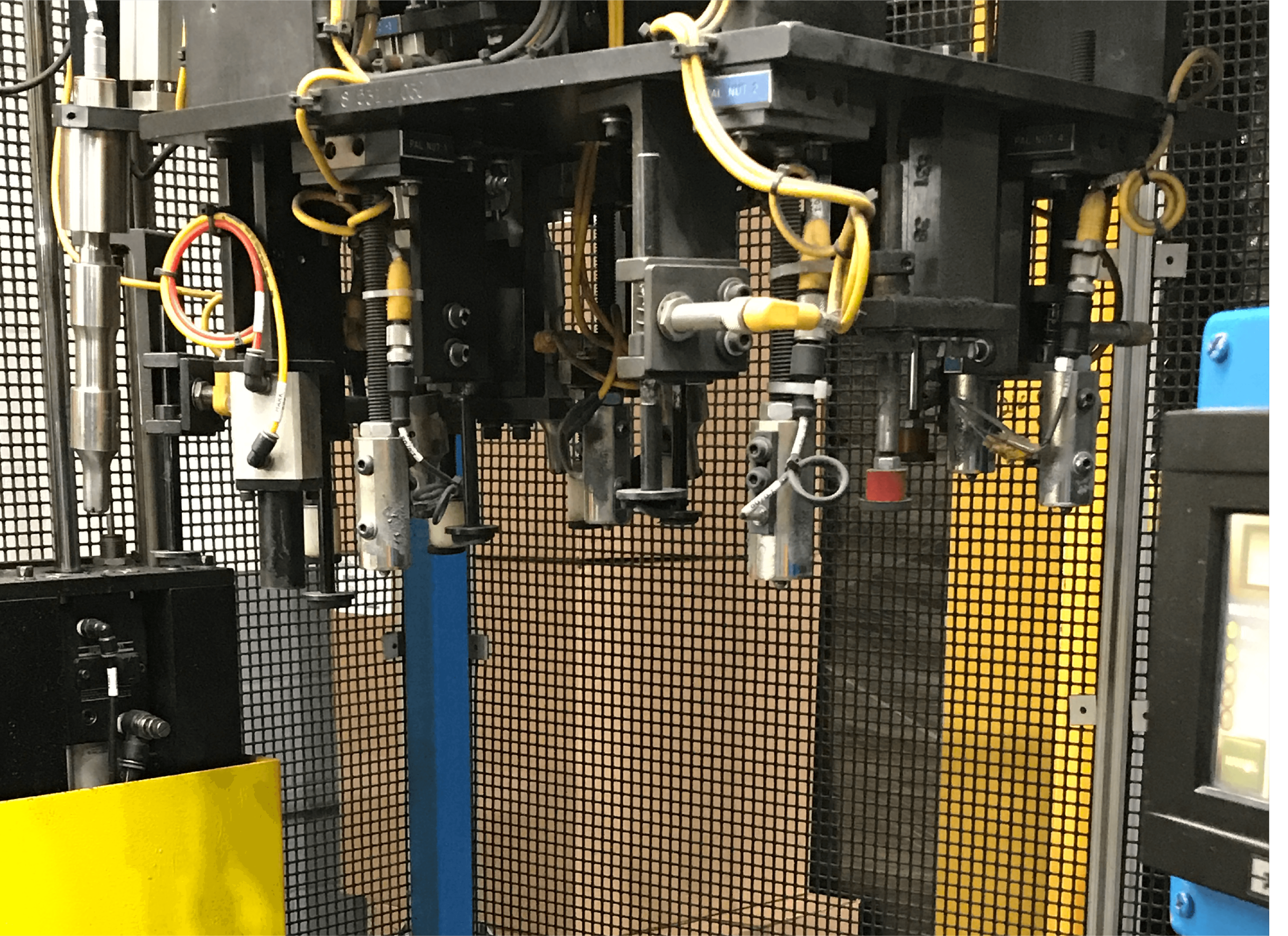

We continually seek to improve the efficiency, speed, and precision of our manufacturing processes through automation, robotics, and smart manufacturing.

Incorporating automation to reduce human error, improve production speed, and maintain consistent product quality.

Implementing real-time monitoring and data analytics to optimize production lines and reduce defects.

Our cutting-edge research facilities are equipped with the latest technology to support ongoing innovation. These include:

Where we perform mechanical, chemical, and environmental tests on new and existing materials to ensure they meet industry standards.

Equipped with 3D printers and CNC machines for rapid prototyping and product testing.

Small-scale production lines that allow us to test new manufacturing processes and materials before full-scale production.

For testing how materials and products perform under extreme conditions like high heat, UV exposure, and moisture.

We believe in the power of collaboration to drive innovation. That's why we work with a variety of partners, including

Collaborating with universities and research organizations to stay at the forefront of material science and plastic technologies.

Partnering with experts across various industries to ensure our solutions meet the specific needs of sectors like automotive, consumer, commercial, industrial and sustainable packaging.

Engaging with Canadian and global regulatory agencies to ensure our products comply with the latest environmental and safety standards.

Our R&D processes are designed to seamlessly transition from concept to mass production, ensuring that innovative solutions are commercially viable.

With a dedicated team of engineers, chemists, and designers, we bring expert knowledge to every project.

Our research and development efforts aren’t just focused on Canadian markets but are designed to meet global industry demands, ensuring we stay ahead of international trends.